25 years of Mareiner: a long history

You should never look at a landscape purely in economic terms. But if you do, you have to say that the Mürztal is a classic raw materials region. The first hammer mills were built in Kapfenberg as early as 1446, not only because the Erzberg is so close by. It was also because the Mürz river provided water power. And the lush forests provided the charcoal on which the early Upper Styrian iron industry depended.

But charcoal is only available if the forest is managed and wood is made. The municipal coat of arms of Sankt Marein, on which a saw blade is emblazoned, also bears witness to this. We ourselves do not know how long wood has been processed in Sankt Marein. But we do know who laid the foundations for wood processing on a grand scale: Alois Posch, born in 1843, who was destined for a remarkable career despite his illegitimate origins. Posch inherits a large farm from his biological father, which he skilfully expands with additional property.

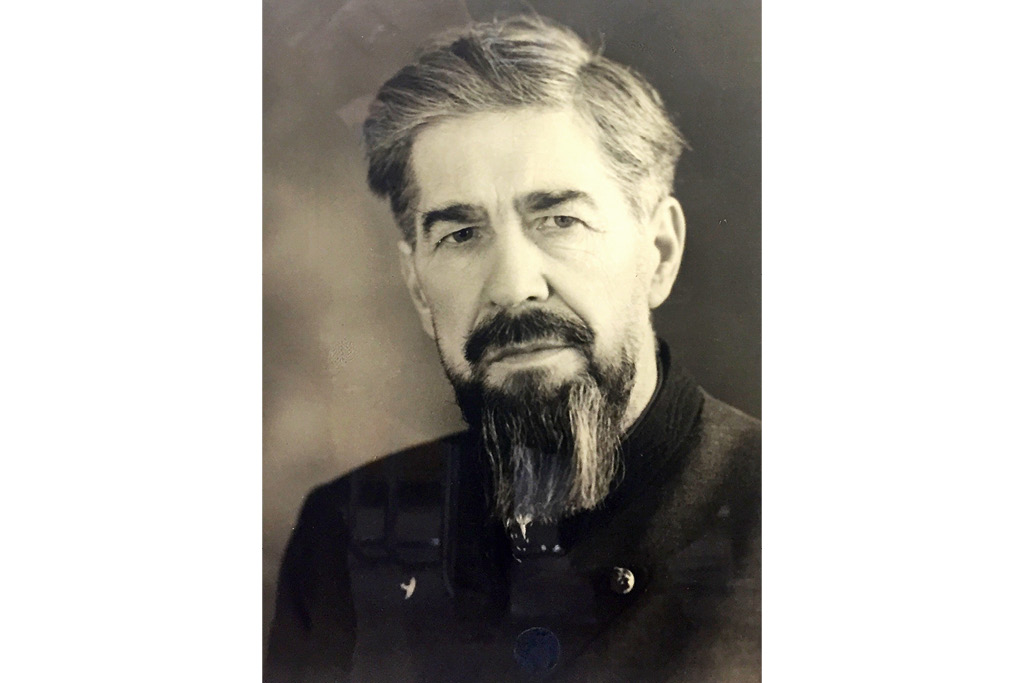

Adolf Mattner © Mareiner

Green electricity at the Graschnitz Bridge

Posch, who also made a career in politics – including as a founding member and first chairman of the Styrian Farmers’ Association, mayor of Marein, member of the provincial parliament in Graz and the Reichstag in Vienna – also acquired a mill and a sawmill at Graschnitzbrücke. He operated both early on with electricity from two hydroelectric power stations, the first of which is said to have gone into operation at Graschnitzbrücke as early as 1885. What is certain is that the second power station in the Au supplied the electricity that switched on the lights throughout Marein from 1902. In other words, the Posch sawmill was already a fairly modern operation in terms of sustainability.

The Mattnersiedlung and a curiosity

It wasn’t until the 1930s that the local timber business truly gained momentum. In 1932 – or 1934 – Adolf Mattner went into business for himself as a “Sagler” (a woodworker), cutting round timber again at the Posch sawmill. Unfortunately, Mattner didn’t have much time to enjoy the hustle and bustle: he passed away in 1939. His son, Adolf Mattner Jr., took over the business together with his brother-in-law, Alois Allinger. The order book filled up, sales increased, and the Mattner sawmill had to constantly hire more staff. This, in turn, created a need for housing, which was unavailable in St. Marein. As a result, Mattner began building his own company settlement in 1939.

Curiously, the land purchase for the Mattnersiedlung – as it is still known today – was only officially completed in 1941, by which time half of the settlement had already been built. By the time construction was finished, 36 apartments and eight so-called “bachelor rooms” were available. It was anything but common at the time for every apartment to have not only running water but also its own toilet and bathroom.

The golden years

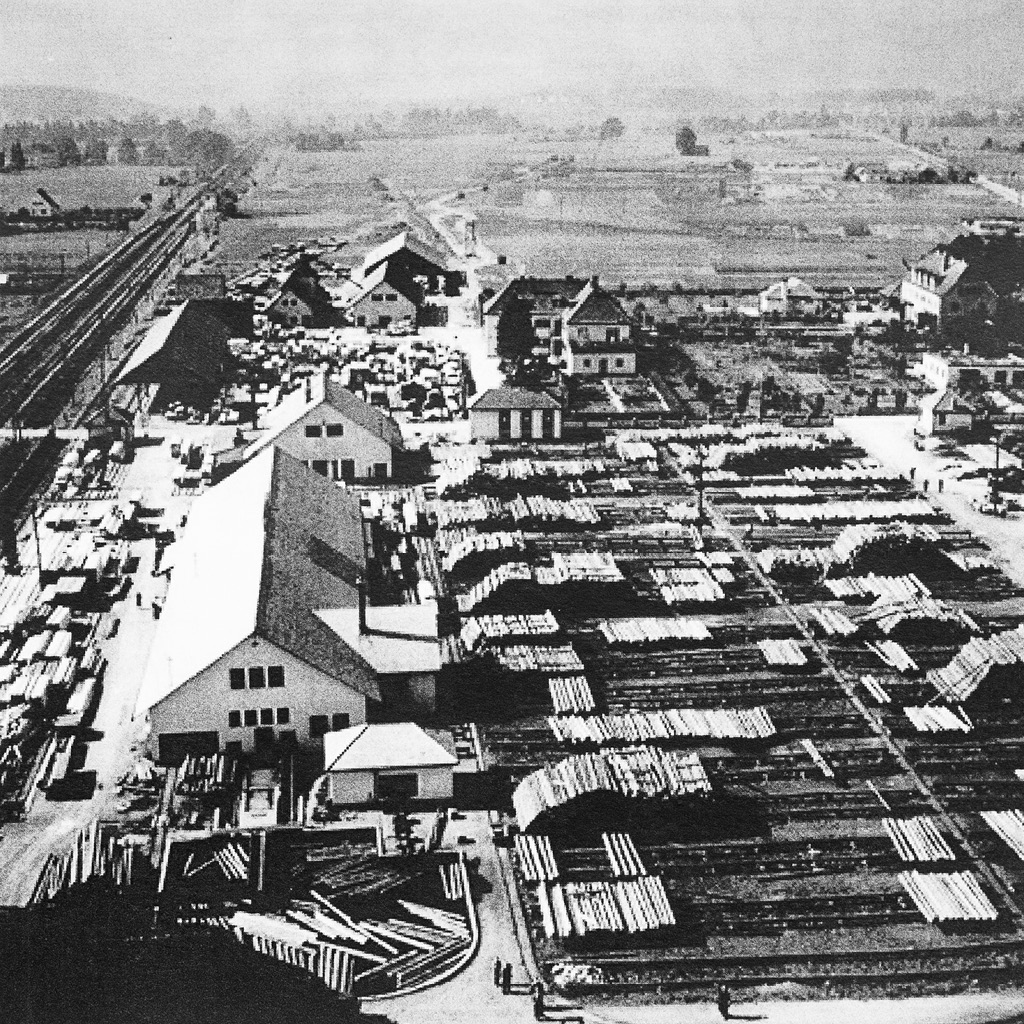

The golden years dawned after the Second World War: Allinger and Mattner invest heavily – including in the maximum level of automation possible at the time. “Der Mattner”, as the company is known locally, produces around 40,000 cubic metres of softwood – an impressive amount for the time.

What is also impressive, however, is that Mattner was already focusing on exports in the 1950s, even before the start of the so-called economic miracle. Walter Allinger established business relations with Italy and, above all, the Middle East: after Mattner had already delivered to Turkey and Algeria, Saudi Arabia, Kuwait, Dubai and Oman became the next markets. Iran, Iraq, Libya and Yemen will be added step by step. Mattner blossoms into Austria’s largest timber exporter and is even allowed to use the national coat of arms as a recognised leading company.

At the Port of KopeR

The boom in St. Marein is also reflected in the trading port of the Slovenian coastal city of Koper, which Mattner prefers to use for exports over the ports of Trieste and Rijeka. With capital from Mattner, dedicated storage facilities for Austrian timber are built in Koper.

In the 1980s, Mattner’s steady expansion reached its peak, with 70,000 solid cubic meters of sawn timber production. A significant part of the family business’s success is due to Elsa Mattner, whose highly developed sense of social responsibility is still vividly remembered by the elderly in St. Marein.

Despite her kindness, a rift occurs within the two families involved in the business: In 1988, the company is split into the Allinger-Mattner Wood Industry and the Dr. Adolf Mattner Wood Industry. The Allinger branch focuses on trade and export, while the Mattner side takes care of the sawmill.

Separation with a Fatal Blow

The separation is marked by bad luck: Both the elder Mattner and the elder Allinger pass away in the same year, and both companies quickly fall into turmoil.

“At the sawmill, they missed the technological developments and failed to take the next step,” says Mareiner founder Hannes Dietrich, who will soon appear in St. Marein.

When investments were eventually made, unfortunately, some critical wrong decisions were made, which ultimately dealt Mattner the fatal blow.’ This fatal blow comes in 1994, when Mattner Holzindustrie has to file for bankruptcy. By that time, the former sister company had already disappeared years earlier, merging into the Mayr-Melnhof empire.

Dr Meysel, please

This marks the low point in the history of the local timber industry for the time being. It is hoped that Dr Siegfried Meysel will reverse the trend far beyond the local area: as the former CEO of both paper manufacturer Leykam and OMV, the honourable Styrian brings a wealth of management experience and an extensive network with him when he takes over the remnants of Mattner and turns it into Mürztal Wood Industry with the abbreviation MHI. As he looks through old application documents in the boss’s office, he is taken aback by one name: he is very familiar with the name Dietrich. Meysel picks up the phone and makes sure that the young timber specialist, whose first name is Hannes, is indeed the son of the forester who has been looking after Meysel’s hunting grounds for years. After an introductory meeting, Dietrich is hired as production manager.

Out of youthful recklessness

What followed still makes him shake his head in amazement today: With youthful enthusiasm and a good dose of recklessness, he campaigned for the continued existence of the saw. Together with Bert Windisch, Franz Hölbling and Norbert Harrer, he follows in the footsteps of Mattner and Meysel and continues the business under the name “Die Säge St. Marein”. Shortly afterwards, they opened the timber market, which still exists today, to establish a second mainstay.

However, the economic ground is hard: “Suddenly there were four of us alone on the huge premises and we were confronted with the mistrust of suppliers who, after two bankruptcies in two years, wouldn’t have bet a penny on us.“

The office in the break room

Surprisingly, the quartet proves to be persistent and tenacious – qualities that are urgently needed in this situation: “Our first office was today’s break room, and the lockers in there were our filing cabinets. The photocopier took a minute for each sheet and made the table shake. In summer, it was so unbearably hot from 2 p.m. onwards that we had to stop working in the office.“

In small steps, the company is recovering and growing – both economically and in terms of the product range. “I was always looking for ways to add more value,” explains the production manager. A customer who asks for finished boards sets the saw on its way, which begins to offer its boards planed as well. An extra shift is often put in late in the evening, even after the office closes, if the order situation requires it.

A lucky coincidence occurs when a French timber importer is looking for suppliers in Austria. The Marein boards found favour and the company gained its first international trading partner. The money earned is of course invested straight away – primarily in machinery and equipment. A milestone for the company is the purchase of the current office building in 2006, which represents a quantum leap in the quality of working conditions.

From cutting to refining

The sawmill gradually becomes a wood processing company. On 13 February 2011, the last log runs through the saw. That was the end of pure cutting and since then Mareiner has been a pure wood finisher, emerging stronger from the major financial and economic crisis of 2008 and 2009. Since then, Mareiner has not only been a major player nationally, but also internationally.